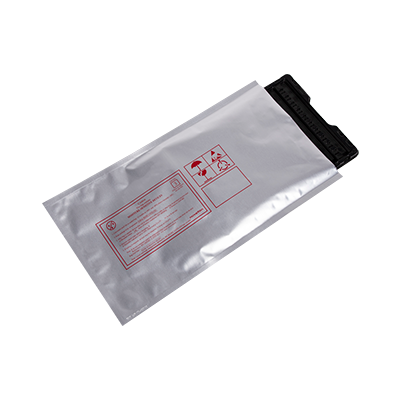

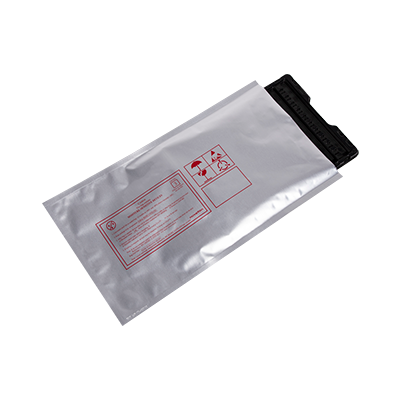

Anti-static aluminum foil bag is a special outer packaging for packaging electronic components, precision machinery and equipment, chemical raw materials, optoelectronic products, route boards, etc. which are sensitive to static electricity and have moisture-proof requirements. It is characterized by moisture-proof, anti-static, anti-electromagnetic interference, high barrier, light-shielding, high and low temperature resistance and corrosion resistance. However, the quality of anti-static aluminum foil bags on the market is various, so choosing a high-quality pouch is crucial to guaranteeing the safety of your products. This article will introduce some ways to judge the quality of anti-static aluminum foil bags.

1. Appearance Quality

According to national standards GB10005-88 and QB/T1871-93, the appearance of anti-static aluminum foil pouches should be flat, wrinkle-free and well sealed. It should not have obvious

bubbles, cracks, pores and composite layer peeling phenomenon. The color should be normal and free from odor, smell and adhering foreign matter. The bag should not have perforation or

rupture, and there should be no false seal in the heat seal position.

Test Items and Indicators | Request |

Appearance | Flatness | Should be flat, no wrinkles, good sealing edge |

Bubbles, cracks, pores and composite layer | No obvious bubbles, cracks, pores and composite layer peeling phenomenon |

Color, odor | Normal color and luster, no peculiar taste, smell and adherence to foreign matter. |

Perforation and rupture | No perforation and rupture |

Heat sealing | No false sealing in the heat sealing position |

2. Printing Quality

Observe whether there is an obvious third color at the splicing of the two colors, and whether there are phenomena such as pulling, foggy plate, blocking, and leakage of printing. The higher

the printing quality, the better.

3. Firmness

To test the firmness of the heat seal, you can use the composite interlayer peeling method, hand handful of rubbing 10 times, observe whether there is obvious delamination phenomenon.

In addition, a drop test at 80cm can be performed to detect whether the bag leaks or ruptures.

4. Anti-static performance

High quality anti-static aluminum foil bags should have good anti-static and static shielding performance. It can be evaluated by indicators such as exterior resistance test and static induction

peak voltage test. Generally speaking, the resistance value should be between 10^8-10^11Ω. When buying anti-static aluminum foil bags, you can refer to the relevant test reports to find out

whether their anti-static performance meets the requirements.

5. Quality Certification

High-quality anti-static aluminum foil pouches usually obtain relevant international certifications, such as ISO 9001 quality management system certification, ISO 14001 environmental

management system certification, ROHS certification, REACH certification and so on. When purchasing anti-static aluminum foil bags, you can ask the manufacturer to provide relevant

quality certification to ensure the quality and reliability of the bags.

When choosing high-quality anti-static aluminum foil bags, please recognize the veteran manufacturers with relevant qualifications. XCGS has five major production bases and eight factories,

focusing on anti-static and new energy packaging in high-tech fields such as chips and semiconductors, and transportation and biodegradable packaging in the field of e-commerce logistics.

We have 300+ production lines and more than 20 years of packaging experience. Large scale, high quality, short delivery time, and can be customized according to customer needs. If you have

related needs, you can contact us, we will serve you wholeheartedly!

18915559236

18915559236 xcbxa@xcgs.com

xcbxa@xcgs.com