Recently, there has been a dramatic increase in rainfall due to cold air and typhoons. Outside the house is rain patter, inside the house is damp and wet.

Clothes don't dry, traveling is inconvenient, and bedding is stained with dampness. So drying your clothes, using umbrellas, and changing bedding ...... are all kinds of little troubles during the rainy season, and they're everywhere.

In addition to the trivial chores, more worrying is that the humid and hot environment is very easy to make the walls and furniture breeding mold. Not only affects the beauty of the home, but also very harmful to the body if people live in a moldy environment for a long time.

The problem of rising damp has been a concern since ancient times. Rising damp is widely mentioned in Victorian literature and the Public Health Act of 1875 introduced a requirement for

damp-proofing of walls to prevent rising damp.

In 1885, the financier and philanthropist Sir Henry Burdett explained the need for an effective damp-proofing process to prevent rising damp in his publication Helping Health: so that air and

moisture do not rise into the house from the ground beneath the floor, we must now turn our attention to the walls, which are just as necessary to prevent the rise of damp. If you plant a brick

or stone wall on a floor capable of retaining moisture, the damp will inevitably creep up the wall according to the law of capillary attraction, unless you take steps to arrest its progress. The way

to prevent this from happening is to insert a layer of ceramic above the ground but below the floor, or two layers of cement slate, or some equally effective impermeable material, the number

of layers of brickwork strips inserted between the two layers will stop the moisture from progressing further upwards. Henry Burdett, who was very concerned about the quality of building in

Victorian England, reminded prospective home buyers to check that the house had a damp-proofing layer and to make sure that it was of an effective type.

Currently, 14% of building damage is reported to be caused by mold problems. The main reasons for the easy growth of mold in the home environment are the lack of a moisture barrier and the lack of a proper insulation structure of the external walls: e.g., the insulation filler material of the walls has a poor barrier and is unable to resist the passage of moisture from the air through the walls. Excessive concentration of moisture in the encounter with colder temperature objects, such as wall paint, furniture surfaces, etc., condensation will occur and produce water droplets. When the water droplets attached to the walls, furniture surface for a longer period of time, it will give mold spores to provide a suitable growth of the hotbed, inducing the walls and furniture surface growth of mottled mold.

Thermal insulation plays an important role in buildings, where high requirements for thermal comfort lead to a high consumption of energy for the full heating of all rooms. Approximately 40% of energy consumption can be attributed to buildings, mainly for heating or cooling. Insulation ensures that the surface temperature of a room does not fall below a critical level, thus avoiding condensation and mold formation. Adequate insulation is an essential task to ensure a healthy indoor environment and prevent structural damage.

Today, there are many types of insulation materials on the market, and to achieve the effectiveness of moisture barriers, the industry recommends the use of vapor barriers. A vapor barrier is any

material, usually plastic or foil, used as a moisture barrier that stops moisture from spreading through components such as walls, floors, ceilings or roofs of buildings and packages to prevent

interstitial condensation.

In architectural applications, the surface is usually a very thin, mirrored aluminum foil. The foil can be coated to resist the natural elements or to resist abrasion, can be attached to insulating

materials such as polyisocyanurate, rigid foam, bubble insulation, or oriented strand board (OSB), and reflective tapes can be adhered to the aluminum foil to make a continuous vapor barrier.

Vapor barriers offer the following advantages:

1. thermal properties do not change over time due to compaction, decomposition or moisture absorption

2. thin panels take up less space than large pieces of insulating material

3. can act as a vapor barrier

4. non-toxic/non-carcinogenic

5. Will not mold or mildew

6. radon mitigation agent that will limit radon gas from passing through the floor

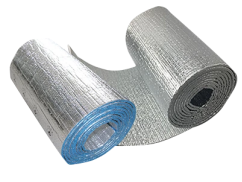

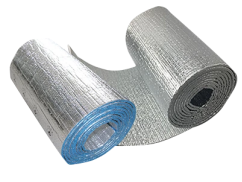

For this reason, when building the exterior wall insulation structure of a house, choose "aluminum foil insulation", which is able to block vapors and fully arm the wall. XCGS Thermal Insulator

helps defeat mold and mildew!

XCGS Heat Insulator is designed with a composite sandwich structure, with the inner and outer layers made of aluminum foil and the middle layer made of PE polyethylene airbag/XPE foam,

which makes the product have a very good barrier effect, so that even if moisture passes through the outer aluminum foil layer and reaches the middle layer of PE airbag layer, convection will

be formed in the middle layer, and it is not easy for it to penetrate into the innermost aluminum foil layer, so that it can achieve the expected barrier effect.

XCGS thermal insulation material has been widely used in the construction industry, construction of roofs, attics, walls can be found everywhere! Not only taking into account the humidity of the rainy season, but also taking into account in the hot summer, blocking the outdoor high temperature heat, the material is flame retardant and fireproof, and in the thermal insulation performance is characterized by low thermal conductivity coefficient, high coefficient of thermal resistance, high reflectivity; oxidation, corrosion resistance, durability and other advantages.

Roof: When aluminum foil insulation is placed between the roofing material and the insulation layer on the attic floor, most of the heat radiated from the hot roof is reflected back to the roof. This keeps

the top surface of the insulation cooler than it would be without the radiant barrier, thus reducing the amount of heat that passes through the insulation into the room below.

Attic: For traditional shingle/tile/iron roofs, aluminum foil insulation can be applied below the rafters or trusses and below the roof boards. This application method covers the insulation underneath the

rafter trusses, creating a small airspace above that faces the entire interior attic space below, reducing direct roof heat.

Wall: Aluminum foil insulation can be used as a ventilated skin around the exterior of a wall. Furring strips are applied to the sheathing to create a ventilated air space between the insulation and

the siding, and ventilation holes are used at the top and bottom to allow convective heat to naturally rise into the attic. Wrapping a home with insulation can reduce the need for air conditioning

systems by 10 to 20 percent, saving energy and construction costs.

We can't avoid the ubiquitous mold spores in the air, but we can choose quality wall insulation, build a relatively healthy home living environment, do a good job of mold prevention and control

from the source and pay attention to the ventilation habits of daily life, even in the wet and rainy seasons, the chances of indoor mold growth will be greatly reduced.

18915559236

18915559236 xcbxa@xcgs.com

xcbxa@xcgs.com